- Home Page

- Company Profile

-

Our Products

- Polyethylene Liners

- Buffles Liners

- Side Flatliners

- Bottle Shaped Liners

- Reinforced Polyethylene Liners

- Black Conductive Liners

- LDPE Canal Liner

- Industrial Conductive Liner

- Agricultural Pond Liners

- LDPE Pond Liners

- 3 Layers Plastic Liner

- Polyethylene Industrial Liner

- Plastic Liner LDPE

- LDPE Transparent Plastic Liners

- 12mm LDPE Plastic Liner

- LDPE Plastic Pond Liner

- Agriculture Film

- Storage Bags

- Mulching Films

- Vermi Bed

- Fruit Cover

- Silage Storage Bag

- Plastic Film

- Liner Bag

- Polyethylene Liners

- Contact Us

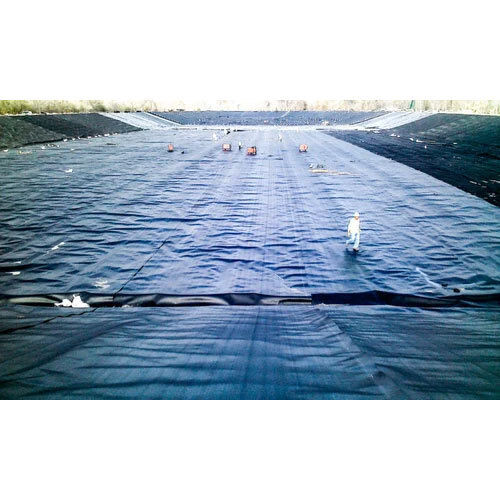

Reinforced Polyethylene Liners

Product Details:

- Product Name Reinforced Polyethylene Liners

- Material Reinforced Polyethylene (HDPE/LDPE) with scrim

- Product Type Liner Sheet

- Film Length Customized (up to 100 m)

- Film Thickness 0.5 mm to 2 mm

- Film Width 2 m to 8 m

- Hardness Flexible

- Click to View more

X

Reinforced Polyethylene Liners Price And Quantity

- 5-10 Piece

Reinforced Polyethylene Liners Product Specifications

- 0.5 mm to 2 mm

- Liner Sheet

- Opaque

- Black

- Reinforced Polyethylene Liners

- Reinforced Polyethylene (HDPE/LDPE) with scrim

- Flexible

- 2 m to 8 m

- Customized (up to 100 m)

Reinforced Polyethylene Liners Trade Information

- 7-10 Piece Per Day

- 1 Week

- Plastic packaging

- All India

Product Description

We are a coveted manufacturer, exporter and supplier of supreme quality Reinforced Polyethylene Liners. Specially used in number of agriculture appliances, the offered liners are made available in several sizes and finishes as per clients' needs. Manufactured by our ingenious professionals using pristine quality basic materials with the aid of progressive techniques, these liners are also tested on defined quality parameters to ascertain their optimum insulation. Besides, patrons can avail these Reinforced Polyethylene Liners from us in different lengths, finishes and thickness at reasonable prices from us.

Features:

- Excellent heat resistance

- Optimum optical clarity

- Resistant to abrasion and cuts

- Easy to use and remove

High Performance and Durability

Engineered with a woven poly scrim, these reinforced polyethylene liners deliver robust tensile strength, high elongation, and superior puncture resistance. Their flexibility and customized dimensions allow adaptation across varied applications, ensuring reliability where containment performance is paramount.

Resistance to Environmental Stressors

100% waterproof and UV stabilized, the liners excel in outdoor environments. The advanced chemical resistance protects against acids, alkalis, and salts, safeguarding the integrity of ponds, tanks, and industrial process areas. Their opaque black finish also provides additional UV protection.

Effortless Installation and Versatile Applications

Supplied in easy-to-handle roll forms with options for heat-welded or adhesive seams, these liners offer swift deployment. Choose smooth or textured surfaces as ordered to suit different substrate needs. Suited for industrial, agricultural, and environmental containment solutions across India and global markets.

FAQs of Reinforced Polyethylene Liners:

Q: How are Reinforced Polyethylene Liners installed?

A: Installation is quick and simple, as the liners are supplied in roll form and can be unrolled and laid out directly onto the desired area. Seams can be joined using heat welding or adhesive methods for secure and watertight placement.Q: What are the benefits of the woven poly scrim mesh reinforcement?

A: The woven poly scrim mesh reinforcement provides enhanced tensile and puncture strength, ensuring the liner withstands mechanical stress, impact, and rough handling during both installation and use.Q: Where are these liners most effectively used?

A: Reinforced Polyethylene Liners are suitable for a range of containment solutions including agricultural ponds, industrial reservoirs, waste management sites, and chemical containment areas due to their waterproof, chemical-resistant, and UV-stabilized properties.Q: What thickness and dimensions are available for these liners?

A: Film thickness ranges from 0.5 mm to 2 mm, widths from 2 m to 8 m, and lengths are customizable up to 100 m to accommodate a variety of containment requirements.Q: What processes ensure the seams of the liner remain waterproof?

A: Seams are sealed using heat welding or adhesive bonding, both of which create continuous, watertight joints that maintain the liners 100% waterproof integrity.Q: When should textured versus smooth surface finishes be chosen?

A: A smooth surface is recommended for easy cleaning and liquid containment, while textured finishes may be preferred in applications requiring increased friction or slip resistance, depending on site conditions and customer preference.Q: What chemicals do these liners resist?

A: These liners demonstrate excellent resistance to a wide spectrum of chemicals, including acids, alkalis, and salts, making them ideal for industrial and agricultural environments where chemical exposure is common.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email